Click here for the Ultra-HECS Controllers Data Sheet

Ultra-HECS™ Controller Overview

Summit’s Ultra High-Efficiency Control System (Ultra-HECS) uses input from an ambient temperature sensing RTD in series with one or more surface temperature sensing RTDs, controllers, and solid state relay circuitry to provide the ultimate in energy-efficient roof ice melt system performance.

The ambient temperature sensing controller allows Summit’s roof ice melt panels to be powered on only when the ambient temperature is between the Heater-On set point and the Low-Temperature Cutout set point which are both field-adjustable.

When this condition is met the Ultra-HECS will allow the surface temperature sensing controller to adjust the power level to Summit’s roof ice melt panels to maximize efficiency and keep them at the desired, field-adjustable temperature set point. As temperatures drop and winds increase, the controller increases the heating cable output.

| EXAMPLES OF STEADY STATE POWER VERSUS AMBIENT CONDITIONS: |

|

|---|---|

| Weather Conditions |

Percent of Steady State of Power |

| 27-30°F, Light Winds | 20-25% |

| 27-30°F, Strong Winds | 35-50% |

| 20-25°F, Light Winds | 40-60% |

| 20-25°F, Strong Winds | 50-70% |

| 10-15°F, Light Winds | 60-90% |

| 10-15°F, Strong Winds | 100% |

Figure A: Energy Loads for Various Weather Conditions

General Information

Summit’s Ultra High-Efficiency Control System (Ultra-HECS™) is UL Listed and has been updated with the most modern technology available to provide the most reliable performance ever. It is specifically designed to combine the patented energy efficiency of the PRO® and LT® Roof Ice Melt Systems with multiple sensors to dramatically reduce energy consumption.

A temperature sensor measures the outside air temperature and only permits the Summit panel controllers to power the heating cable when the ambient temperature nears freezing (e.g., 34°F). The Ultra-HECS controller then maintains the roofing panels above freezing (e.g., 40°F) so that snow melt will not re-freeze and form icicles and ice dams at the eaves. Summit’s systems use self-regulating heating cables as the source of heat and are designed to handle most worst-case winter storm conditions.

True Energy Efficiency

Our Ultra High-Efficiency Controllers are designed to optimize heater performance to use a fraction of the energy required by competing systems. For example, Summit’s patented PRO Roof Ice Melt System already uses 1/3 less electricity than any other Class 1 heavy snow area system, and Ultra-HECS further enhances heating efficiency by allowing several precise control points and parameters to be used, enabling Ultra-HECS to modulate power to the heaters and keep energy consumption to a minimum.

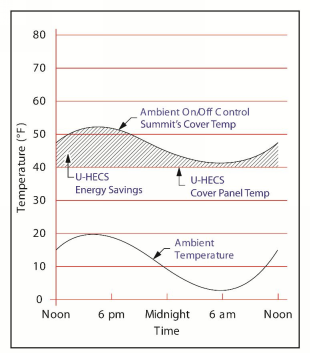

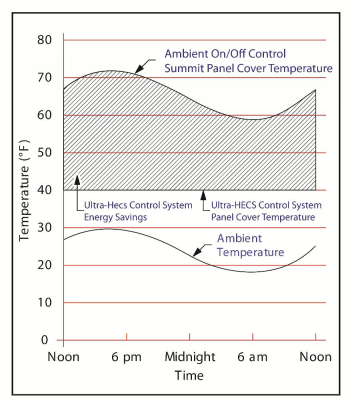

If a simple ambient temperature sensing controller were used, the heating systems’ Cover Panel temperature would range from 40°F during extreme winter conditions (10-15°F, snowing, windy) to 70°F during milder winter conditions (25-32°F, calm, sunny). Figures B and C show the relative energy consumption for an ambient on/off controlled system versus the Ultra-HECS for two winter days. The Ultra-HECS reduces Summit’s energy consumption by 40-60% during mild winter days and by 10-40% during colder and stormy winter days. For the average winter, energy savings should average around 35%.

Figure B: Extreme Winter Day

Figure C: Mild Winter Day

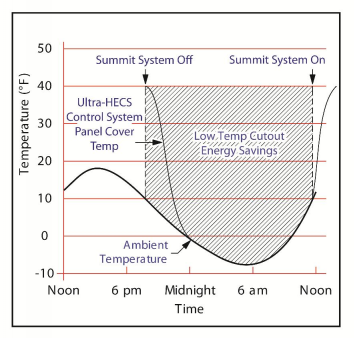

Low Ambient Temperature Options

Snow melt at the roof/snow interface depends on roof snow depth, ambient temperature, roof design, interior building heat, building insulation and solar gain. However, there are low ambient temperature conditions when snowmelting simply cannot occur. In many cases, temperatures below a 0°F will create “no snowmelting” conditions. The Ultra-HECS includes a control panel mounted solid state controller and an eave soffit mounted RTD temperature sensor, that will detect these low ambient temperatures and de-energize the heating system to save energy. The Low Temperature Cutout (LT Cutout) set point is easily field-adjustable.

The temperature at which Ultra-HECS turns on the heaters can be set and adjusted at the control panel (we recommend 36-40°F). In addition, the LT Cutout feature can be set at the control panel (we recommend 0°F to start) and can then be adjusted up or down based on the local winter conditions for the building. For example, if 10°F is the proper LT Cutout set point and the winter had 150 hours below 10°F, up to 10% energy savings can be realized when compared to a control system without the LT Cutout feature. Figure D demonstrates how the LT Cutout option would typically operate without the LT Cutout feature operating.

Summary

When compared with standard ambient-only temperature control, the Ultra High-Efficiency Control System can provide up to 50% energy savings for a typical winter, particularly in heavy Class 1 Snow Areas. In addition, up to 10% more energy savings can be realized when using the LT Cutout feature.

Specifications

- UL Listed by Certified UL-508A shop designed, constructed, tested, and approved

- Designed to separately control multiple heater zones for greater efficiency

- Includes power distribution blocks and modular, mounted branch circuit breakers and 30mA ground fault (EPD) breakers

- Integrated timers to delay operation for interval activation between circuits to minimize peak inrush current load

- Utilizes solid-state relays for quiet and efficient operation

- Accommodates 1-phase or 3-phase incoming power

- Operates on 208, 220, 240, or 277V

- Ambient controller sensor displays ambient temperature and Heater-On set point

- Multiple separate control zones available

- Up to 18 branch circuits with ground fault protection

- Summit Panel Cover controller sensors display Panel Cover temperature and set point

- NEMA 1 or 4/12 enclosures available

- PROUDLY built in the USA